Best Performance, Inc. has developed a new, innovative, vertical bulk material conveyor. The lift tremendously reduces degradation of materials, increases efficiency, and helps improve the safety of the work place due to its extreme health hazard prevention components, such as being virtually dust free. The new ideas behind this conveyor are ground-breaking and extremely beneficial to companies that utilize bulk material handling equipment.

Best Performance, Inc. has developed a new, innovative, vertical bulk material conveyor. The lift tremendously reduces degradation of materials, increases efficiency, and helps improve the safety of the work place due to its extreme health hazard prevention components, such as being virtually dust free. The new ideas behind this conveyor are ground-breaking and extremely beneficial to companies that utilize bulk material handling equipment.

Simplified Design with Reduced Wear

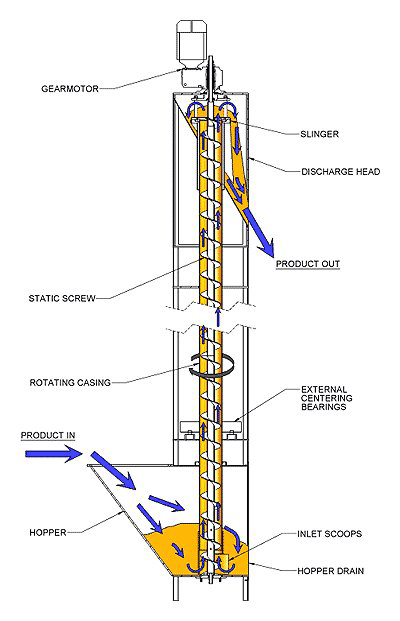

The principal behind this machine is very straight forward. At the center of the machine is a fixed lift screw that is fastened to the bottom of the inlet hopper. A casing with scoops attached rotates about the fixed lift screw. As the casing rotates, the scoops direct product to the lift screw. The interaction between product particles and the rotating casing combined with pressure provided by the scoops forcing product to the screw, causes the product to move up the screw and be discharged at the top. This design helps to insure that the number of parts that contact a customer’s product are kept to an absolute minimum. Please see Figure 1 to the right to get a visual idea of how the Bulk Material Lift works.

Versatile, Innovative Design

The scalability of this machine depends on a few factors that the customer can provide to us, such as bulk density of material that needs lifted (lbs per cubic ft.), moisture content, flow rate requirements (pounds/tons per hr.), and special considerations (i.e. stainless steel contact parts for food grade material). We also offer an optional Variable Frequency Drive and RPM precise control so that you can customize and identify an exact precision flow rate for your product.

As depicted in the image above, our minimalist design also produces an innovative noise reduction feature for the Bulk Material Lift. Operations are executed much more quietly compared to other conveying methods.

Saving, Safety, Simplified

The final and most important elements to the Bulk Material Lift are the cost savings and safety features. Both attributes can be contributed, once again, to our simplistic design.

- Functioning at a low amp usage rate, we are surpassing the pneumatic conveying systems. Our high efficiency shaves off costs on our bottom line, and we are able to do so without blowers, compressors, vacuums or dust control equipment that is typically needed for an additional expense.

- Few parts equates to few maintenance costs. Wear is reduced, fewer parts are moving and a stout drive unit present in the design. All of this extends your operating life and reduces maintenance costs over time.

- The Bulk Material Lift has a simplified installation process and economizes your floor space. Both elements are also money savers for long term operations.

- Finally, each machine is virtually dust free. With little open area , dust doesn’t come in and we are able to minimize dust combustion – keeping employees safe from explosion risks.

Bulk Material Advantage

The benefits of using the Bulk Material Lift are limitless with a simplistic, innovative design. To talk more about the design, call us today at 1.866.865.5625.